In a distillery, we use two distillation columns in series for ethanol distillation from fermented wash. First column is Analyzer Column and second one is Rectifier Column. We get final product from top of the Rectifier Column, which is an azeotropic mixture of ethanol and water. This final product is also known by the name of Rectified Sprit or RS and contains 95% ethanol by volume.

In fermenters we mix molasses and water with pre-activated yeast. Here, biological reaction in the absence of oxygen takes place and glucose is converted into ethanol and CO2. This we also know by the name of fermentation process. At the end of fermentation process, fermenter contains ethanol in the range between 6 to 11 % by volume.

This reaction mass after completion of fermentation process is known by fermented wash. The ethanol concentration in fermented wash depends on the fermentation technology which we are using.

For traditional batch fermentation process ethanol concentration is low in fermented wash, around 7-9% by volume. While in Fed Batch process, which is a semi-batch process it is around 9-11% by volume.

In this article we will discuss the ethanol distillation process from fermented wash. Moreover, we will do energy balance and subsequently discuss the energy saving opportunities also. This is very important to make your alcohol business more cost competitive and sustainable.

Table of Contents

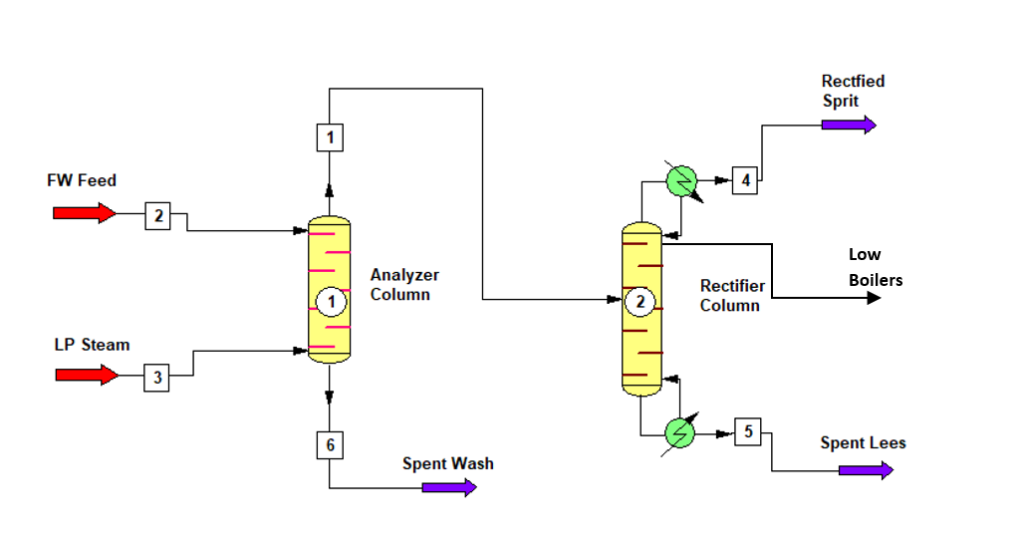

Process Flow Diagram for Distillation Section

To understand the ethanol distillation process in a distillery you can refer the below figure. This set up is to produce Rectified Sprit or RS. Here you can see, we have two distillation columns in series. The fermented wash from fermenter is pumped into the analyser column.

Analyser Column

In analyzer column we feed fermented wash contains 7-11 % ethanol contents by volume at top tray. While, live steam enter at bottom of the column. This is also a steam stripper column, which we use to strip off all the ethanol entering with feed. The top of analyzer column contains ethanol and water and this feed into the rectifier column. Bottom of the analyzer column has negligible ethanol and is an effluent stream. This effluent stream is known as spent wash in distillery. The spent wash contains bio mass and other harmful chemicals, which are dangerous for the environmental sustenance. Therefore, proper treatment of the spent wash is inevitable to ensure zero liquid discharge from the distillery.

Rectifier Column

In rectifier column we recover rectified sprit from the top and bottom is a waste stream, contains negligible amount of alcohol. This effluent stream is known as spent lees. We recycle back spent lees for the molasses dilution process.

Total liquid effluent generation from a distillery can be in the range of 7 – 10 kl/kl of ethanol production. This effluent generation norm depends on the fermentation technology which we are using.

Both the columns are tray type columns. This is so because the fermented wash contains bio-mass, salts and suspended solids. If we use packed column it will choke the column packing. Moreover, in analyser column we generally supply direct live steam for heat supply. The reason is same, as bottom stream of analyser column will choke the reboiler tubes.

Furthermore, we need to remove low boilers from rectified sprit, which forms during molasses fermentation. To do this we need to purge out small quantity frequently, from the top of the rectifier column.

So, to understand the material and energy balance for RS distillation we will take an example. The basis for process calculation is in next section.

Operating Data for Distillery

For our study we will take an example of rectified sprit distillation or ethanol distillation setup in a distillery. The feed rate to the analyser column is 30000 kg/h and ethanol concentration in feed is 10 % (vol/vol). Analyser column feed inlet temperature is 80 0C.

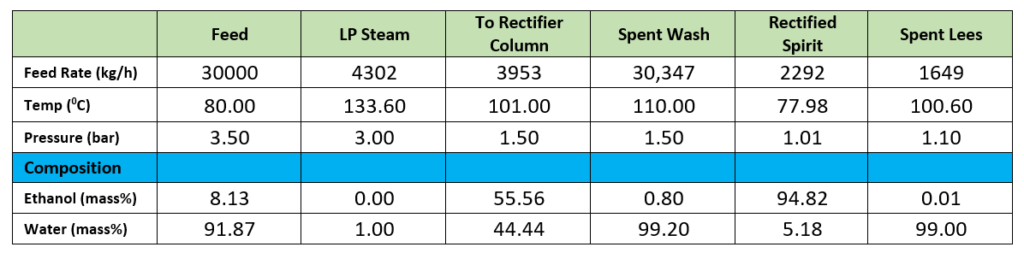

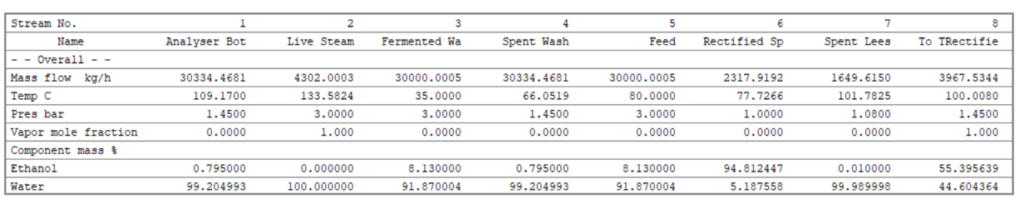

Material Balance and other properties of ethanol distillation is given in below table:

Heat balance for Analyzer Column

For estimating steam consumption for analyser column, you can follow below steps.

Feed rate to the analyser column is, F= 30000 kg/h, analyser column bottom temperature, T1= 110 0C, Heat capacity of feed, Cp1= 1.0 kcal/kg0C, Latent heat of analyser column top vapor, LH1= 358 kcal/kg.

Since total alcohol in feed is 30000*8.13=2439 kg/h, and ethanol concentration in analyser column top is 55.56 wt%. So, analyser column top flow rate will be, M1= ((2439) – (30347*0.8/100)) *100/55.56 = 3953 kg/h

Therefore, heat load on analyser column will be, Q1= F*Cp1*(110 – 80) + 3953*LH1 = 30000*1.0*(110-80) + 3953*358 = 2,315,890 kcal/h

We will use 3.0 bar saturated steam for heating. So, latent heat of steam LH2= 517 kcal/kg and saturated temperature T1= 133.7 0C.

Hence steam required for analyser column will be, W1= Q1/(LH2+Cp*(133.7-110)) = 2,315,890/(517+1.0*(133.7-110)= 4302 kg/h

For Analyzer Column calculate LP Steam feed rate will be, W1 = 4302 kg/h. Here we are feeding live steam into the column directly. However, it will be slightly higher side because of heat loss to surrounding and leakages from the piping and fittings. For this purpose, you can consider around 5% extra steam. Therefore, actual steam consumption for the analyser column will be around, W1’= 4302*1.05 = 4517 kg/h.

Heat Balance for Rectifier Column

So, to estimate the steam requirement for Rectifier Column. We need to know reflux ratio for the rectifier column. In our case we are considering Reflux Ratio of 1 : 4, hence vapour rate from the column will be,

M2 = (1 + 4) * 2292 = 11,460 kg/h (here, 2292 kg/h is the distillate rate from rectifier)

Latent heat of vaporization for the rectified spirit is LH2 = 219 kcal/kg. Therefore, heat load for condenser will be Qcond = 11,460 * 219 = 2,509,740 kcal/h.

Heat duty for rectifier column reboiler can be estimated by

Qreb = Qcond – heat supplied by the vapour feed

Latent heat of the vapour feed to the rectifier column is LH1 = 358 kcal/kg. Hence heat load on rectifier column reboiler will be

Qreb = 2,509,740 – 3953 * 358 = 1,094,566 kcal/h

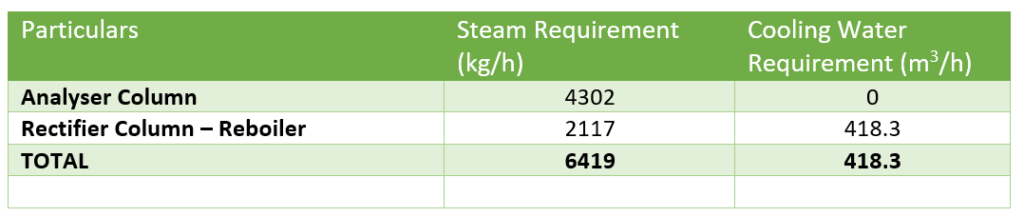

Steam & Cooling Water Requirements

Latent heat of 3 bar steam is LH2 = 517 kcal/kg. Hence steam requirement for the rectifier column will be

W2 = Qreb /LH2 = 1,094,566/ 517 = 2117 kg/h

Hence total steam requirement will be W = W1 + W2 = 4302 + 2117 = 6419 kg/h, considering 5% heat loss from the system steam requirement will be W’ = 6419 * 1.05 = 6740 kg/h

If cooling water supply temperature is 32 0C and temperature difference across the cooling water side is 6 0C. We can estimate the cooling water requirement W3 = Qcond/ (Cp * ∆T) = 2,509,740/(1.0*6) = 418,290 kg/h = 418,290/1000 = 418.3 m3/h.

Summary of Energy Balance

So, we can summarize the steam and cooling water requirements for both the columns as below:

RS (Rectifier Sprit) Production Capacity: 2292 kg/h or 55 TPD

Steam Consumption Norm: (6419/2292) = 2.80 kg/kg

Simulation Results for Distillery

In this section you can refer the ethanol distillation simulation results to cross check our above calculations. We will also see the design outputs for columns, reboiler and condenser.

From above simulation results you can see our material balance and heat balance calculation are OK.

Column Sizing Results

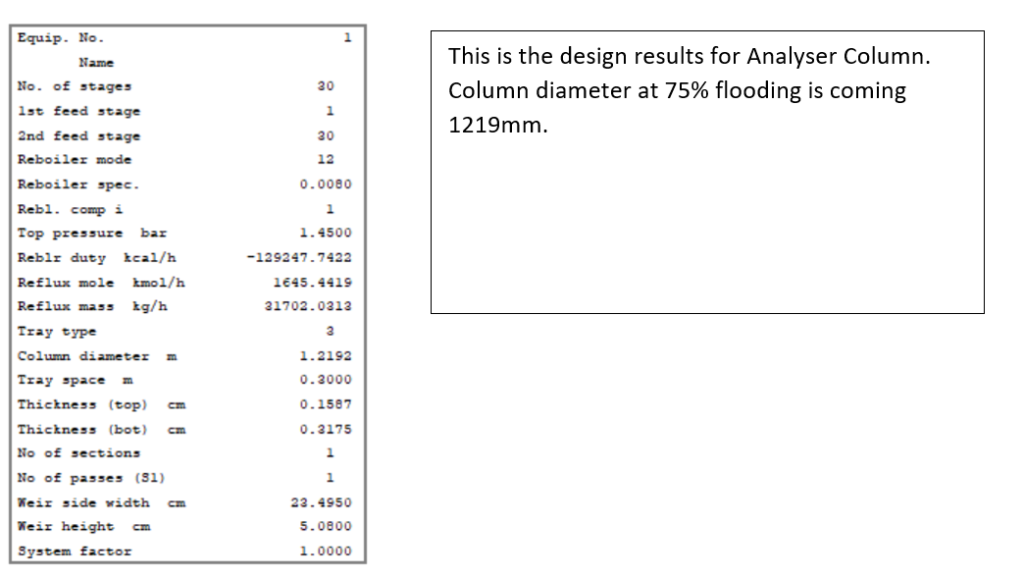

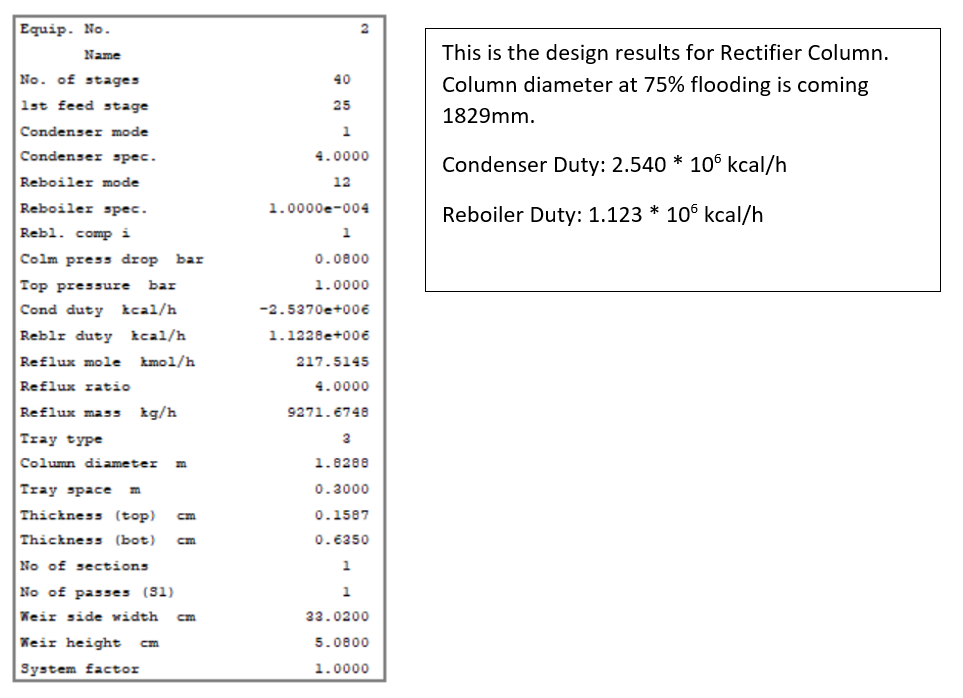

Now we will check the column sizing for this I am considering tray type columns. For analyser column we will consider 10mm diameter holes and 300mm tray spacing. And, for rectifier column we will take 5mm diameter holes and 300mm tray spacing.

Below are the results from simulation:

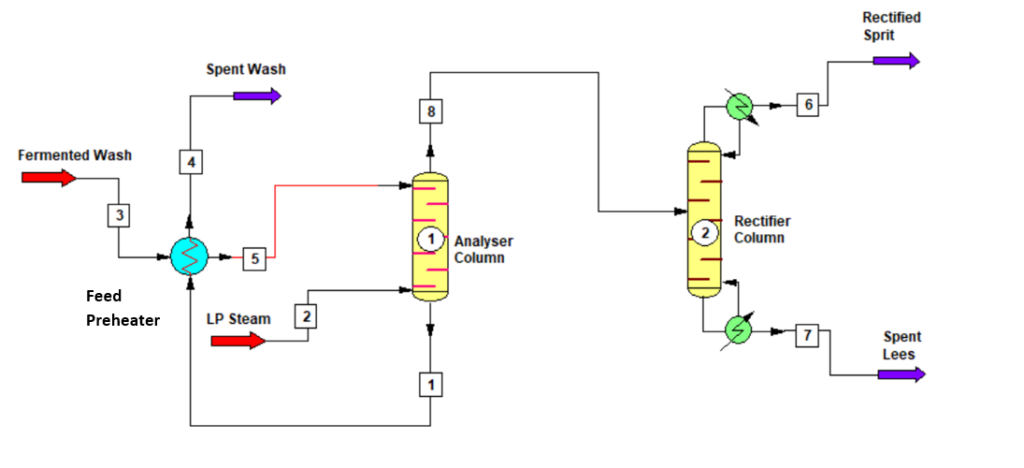

Energy Saving opportunities

So, from above calculations you can see steam consumption norm is 2.80 kg/kg. Therefore, if we take steam price @1.40 Rs/kg, then steam cost will be 2.80*1.40 = 3.92 Rs/kg. And for 50 TPD distillery capacity it will be 50000*3.92 = 196,000 Rs/day. For 280 days distillery operation this steam consumption bill will be 280*1.96 = 548.8 lacs. So, it is a huge money, if we target 10% reduction it will be 54.88 lacs.

Hence, various opportunities for energy savings can as below, which you can work out.

- Boiler water feed pre-heating using spent wash stream. In our case this is at 66 0C and we can cool it down up to 45 0C. So, total energy saving can be ES1= 30347*1.0*(66-45) = 637,287 kcal/h.

- Heat recovery from rectifier top is possible. Using this waste heat, we can preheat up to 67 0C any plant stream or boiler feed water. We need to install an additional heat exchanger in series prior to condenser. If we consider recovery of latent heat only then, available heat opportunity will be ES2= 11460*219 = 2,509,740 kcal/h. This heat recovery will reduce cooling water requirement also. Which is ultimately saving of power consumption.

- Other opportunity we can consider is heat recovery from rectifier column bottom. Here, spent lees is available at 101 0C and can be cooled down to 45 0C. Therefore, available heat for feed preheating is ES3= 1649*1.0*(101-45) = 92,344 kcal/h.

This way if we sum up all the energy saving opportunities ES= ES1+ES2+ES3 = 3,239,371 kcal/h. And, if we convert this energy in 3 bar steam equivalents then, ES/517 = 6266 kg/h. However, major waste heat is available at low temperature levels (66 and 77 0C), still we can use it for feed preheating. Other options for using this waste steam can be VAHP (vapor absorption heat pump), to generate chilled water. Also, we can use heat pump to convert this low temperature level waste heat into high temperature level valuable heat.

So, we can see the heat integration possibilities to extract these available waste heats. This will reduce our product cost and enhance business profitability.

Conclusion

Finally, we can say a thorough process analysis, material and energy balance for our ethanol distillation in distillery is very important. This gives us the insight of our process and enable to find out the possible opportunities for further improvements. I think you can use this article to maximize the energy efficiency of your distillery.

Thanks for your read and looking forward for the comments and feedbacks.

Hi Author, I read your blog the information you have provided is very good I found it very helpful, being one of the top distillery plant in India. I have crafted very good services related to the subject that can surely be helpful for your readers.

Thanks for writing and reading my blog.

First of all, I would like to thank you, I am also working as a distillation operator in the distillery, you have told a lot about the distillery in your blog, which is very important for any person who is working in the distillery and I After reading your blog, I have come to know about distillery to a great extent.

Thank you for your mail.

Thank you , You have explained it in very simple manner.

Thanks…