The chilled water and chilled brine are cold utilities, which we use to remove heat at lower temperature levels than cooling water. We use these utilities in our chemical process industries (CPI) to remove heat from air-conditioning system, process equipment and fluid streams. From cooling water at supply temperature 32 0C, we can achieve cooling up to 35-36 0C. So, using chilled water, we can provide cooling up to 9-10 0C, while with brine chiller we can achieve (-)14 – (-)15 0C temperatures. In our industries we mainly have two types of refrigeration machine. First is based on vapour compression refrigeration cycle, while other one is vapour absorption refrigeration cycle. In this article we will discuss about Vapour Absorption Heat Pump (VAHP), which works on vapour absorption refrigeration cycle.

So, let us understand the fundamentals behind a VAHP working as below.

Table of Contents

What is Vapour Absorption Refrigeration Cycle?

As we discussed above VAHP works upon vapour absorption refrigeration cycle. In this process there are two working fluids – one is refrigerant and other is absorbent. So, to generate chilled water @ 7.0 0C we use LiBr (lithium bromide) as an absorbent and water as refrigerant. And, to generate chilled brine, we use ammonia and water working fluids. Where, ammonia is refrigerant and water is absorbent.

The below are two important properties which are the basis for working a VAHP (with LiBr and water working fluids):

- Boiling point of water is the function of pressure, as we reduce the pressure its boiling point reduces. So, we can see at 6 mmHg absolute pressure water boils at 3.7 0C.

- Second important property is the Lithium Bromide affinity towards water. So, this concentrated LiBr aqueous solution can absorb water vapours.

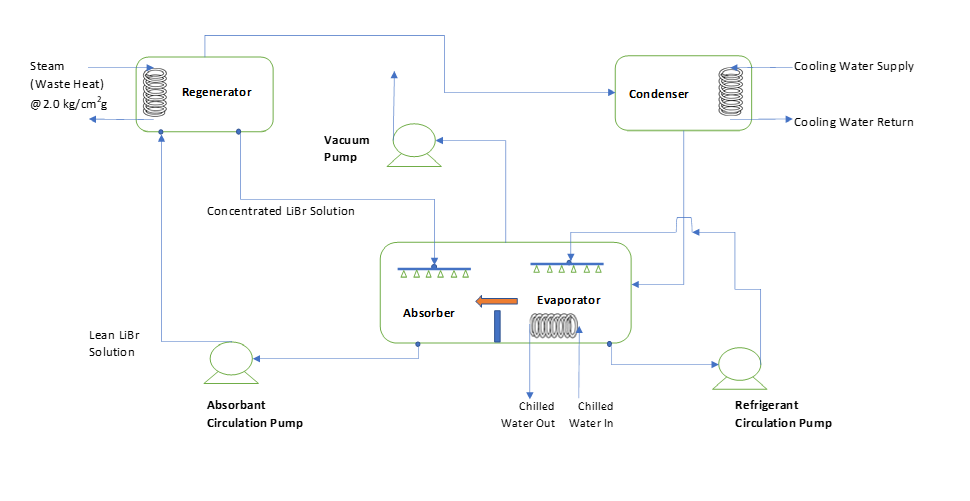

Now, we will see how above two properties works in absorption refrigeration cycle. You can refer the below figure to understand this principle.

Various Part of a VAHP and their Function

A vapour absorption heat pump or VAHP has different sections as we can see in above figure. There is evaporator, absorber, regenerator, condenser, circulation pumps and vacuum pump. The utility of each part we can understand as given below:

Evaporator

In evaporator we maintain vacuum around at 6 mmHg absolute and chilled water provide the heat to this water (refrigerant) for evaporation at 3.7 0C. After supplying heat chilled water cool down to around 7.0 0C. The chilled water inlet temperature to evaporator is around 13.0 0C. These vapour at 3.7 0C from evaporator goes into the absorber section.

Absorber

Where concentrated solution of LiBr (absorbent) absorbs this water vapour. This concentrated solution of absorbent we get from regenerator. And the lean solution of absorbent from absorber goes back into the regeneration section. For circulation of this absorbent, we use absorbent circulation pump.

Regenerator

In regenerator we regenerate lean LiBr solution, by evaporating excess water. For this purpose, we use waste heat, which is a low-pressure steam @ 2.0 kg/cm2g. Here, water evaporates and vapour goes into a condenser, while concentrated absorbent solution goes into the absorber. Other than steam many VAHP operates at hot water also, in that case this regenerator will operates under vacuum. This way we can evaporate water from the lean LiBr solution at low temperatures also. Moreover, VAHP can be double effect type, where we need steam supply at higher pressures. For your clarification the above figure is for a single effect VAHP, having LiBr and water as a working fluid.

Condenser

So, we need a condenser which is a shell & tube type heat exchanger to condense the water vapour generating from regenerator. Here this water is our refrigerant and we use cooling water to condense it. After condensation this refrigerant goes into the evaporator again, which is operating at vacuum of 6 mmHg absolute. This way this refrigeration cycle keeps on working.

We can find the fundamental difference between a vapour compression and vapour absorption is a compressor. In compression refrigeration cycle we use a compressor to compress the refrigerant vapour. While in absorption cycle, we use absorbent to condense/absorb the vapours.

In summary, we supply heat to regenerator using steam and remove heat in evaporator from circulating chilled water. And, remove heat from condenser using cooling water. This way our VAHP generates chilled water at around 7.0 0C temperature. This chilled water temperature depends on the evaporator section vacuum, if vacuum reduces chilled water supply temperature will increase. Simultaneously, condenser cooling water supply temperature is also important. Because condensed refrigerant (i.e., water) temperature will depend on cooling water temperature.

Types of Vapour Absorption Heat Pump

In our industries we can find two types of VAHP first is single effect which require low pressure steam (i.e., around 2.0 kg/cm2g). While second type is double effect VAHP, which operates at higher pressure around 5.0 – 8.0 kg/cm2g steam supply pressure.

In double effect VAHP there are two generators while in single effect we have one generator. So, water vapour generating from first regenerator goes into the second regenerator. This way we can achieve low steam consumption to evaporate the same amount of water from lean LiBr solution.

So, benefit of two effect VAHP over single effect is the specific steam consumption to generate same TR. The specific steam consumption in single effect VAHP is 7.5 – 8.0 kg/TR, while for double effect this as low as 4.5 – 5.0 kg/TR. Therefore, double effect VAHP gives advantage of around 35 – 40% lower steam consumption.

Coefficient of Performance (COP) of a VAHP

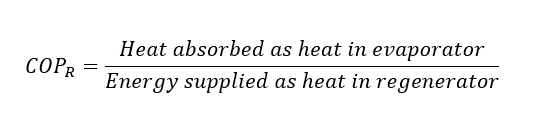

We can measure the performance of a refrigeration machine by estimating it’s COP or coefficient of performance. The COP for a VAHP we can estimate using below relationship:

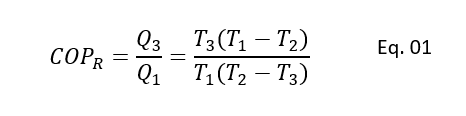

If we designate the Q1 = Heat supplied by steam in regenerator or heat added from source at T1 and Q3 = Heat supplied by chilled water in evaporator or heat absorbed for refrigeration at T3. And, T2 is the ambient temperature. Then, we can rewrite above relationship as below:

So, if our VAHP is operating at 2.0 kg/cm2g and has regenerator temperature 100 0C (373 K) and evaporator temperature is 4 0C (277 K). Considering ambient temperature 35 0C (308 K), COP will be = [277*(373 – 308)]/[373*(308 – 277)] = 1.56.

Cost Benefit Analysis Vapour Absorption v/s Vapour Refrigeration System

Ideally a VAHP is advantageous when we have waste heat available in our plants. When we talk about waste heat is means, we are rejecting this heat into our cooling towers or atmosphere. Moreover, there are conditions where power cost is very high in comparison with steam cost, then use of VAHP is a cost-effective option.

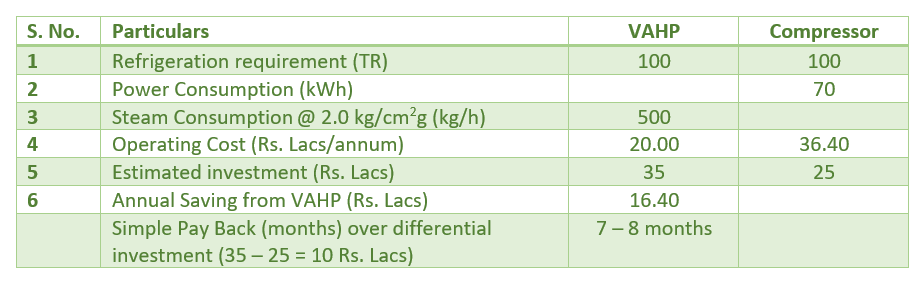

So, to understand the economic feasibility let’s consider a plant where we require 100 TR refrigeration in terms of chilled water. We have option to go for a vapour compressor refrigeration unit or a single effect VAHP. Below table is the working to understand this comparison which can help us to take better decision.

We have made following assumptions for our estimation:

- Power consumption in refrigeration compression system 0.7 kWh/TR

- Steam consumption is VAHP 5.0 kg/TR

- Power cost @ 6.5 Rs/kWh and steam cost @ 0.5 Rs/kg

- Plant operating hours = 8000 hrs/annum

- All other overhead cost is same in both cases

Therefore, from above analysis we can see, by selecting VAHP over refrigeration compressor is preferable. As, there will be annual savings in operating cost around Rs.16.40 lacs. However, investment requirement for VAHP is higher by Rs.10 Lacs (35 -25 = 10). The simple pay back period for the differential investment will be =10*12/16.4 = 7.3 months.

Conclusion

Finally, in this article we discussed about vapour absorption refrigeration system based on LiBr-Water working fluids. This can provide refrigeration requirement up to 7.0 0C. For refrigeration requirements at lower temperature say (-) 18 0C, we use NH3-Water as working fluids. This VAHP operates under pressure to condense the ammonia vapours coming out from regenerator. Subsequently, liquid ammonia is throttled into the evaporator to generate chilled brine utility. From evaporator ammonia gas goes into the absorber, where water is used to absorb the ammonia gas.

So, we should explore the avenues of waste heat available in our plants. Various possible sources can be such as reactor outlet hot gases or heat of reaction, condensate flash steam, hot process streams, hot flue gases, etc. This waste heat we can use to generate low pressure steam or hot water and can use in VAHP refrigeration system. These VAHP refrigeration machines will help us to stop our refrigeration compressor, which are one the major power consumers in our plants. This way we can reduce the overall power consumption, which is ultimately a reduction in variable cost of the product.

Moreover, using VAHP is good for our environment sustenance, where we are not using any harmful refrigerants. Simultaneously, it encourages the use of waste heat available inside the plants to generate low-cost refrigeration. Consequently, which is the effort towards reduce carbon foot prints.

Thanks for reading and looking forward for your comments!!!

Thanks foor finally talking about > Vapour Absorption Refrigeration Cyfle

in VAHP – ChemEnggHelp dorsetfarmersmarkets.co.uk)