In chemical process industries, Multiple Effect Evaporators or MEE we use to concentrate the lean feed stream into concentrated product output. In such processes to concentrate dilute or lean feed stream we need to evaporate lots of water from the input stream (i.e., feed may contain very low concentration 2-3% or less). So, here we can use MEE or Multiple Effect Evaporators to minimize the steam requirement for water evaporation from the lean feed. We should understand, if use single stage evaporator, we need around 1.1 kg steam to evaporate 1 kg of water. While, if we use a three-stage evaporator system roughly 3 kg of water can be evaporated using 1 kg of live steam.

Table of Contents

Steam Economy

The steam economy for a MEE is (kg of steam used/kg of water evaporated from all effects). We can enhance steam economy by increasing number of effects. However, we should evaluate the steam economy v/s fixed cost for the MEE. In our industries most of the effects are 3 or 4 stage only. Using higher number of effects will not increase steam economy substantially, while investment required will be more. Some of the applications where we use MEE are as below:

- Concentration of aqueous feed of Vitamin before feeding into the dryer.

- Raw spent wash concentration before feeding into slop fired boiler.

- Concentration of lean organic effluent stream before feeding into the incinerator and reducing fresh water requirement by recycling evaporated water.

- Waste water concentration, which contain various salts (i.e., NaCl, Na2SO4, (NH4)2SO4, etc.) and recycle the evaporated water to reduce the fresh water and final effluent quantities.

Types of MEE Systems

Based on the feeding orientations, we can categorize MEE operation as described below:

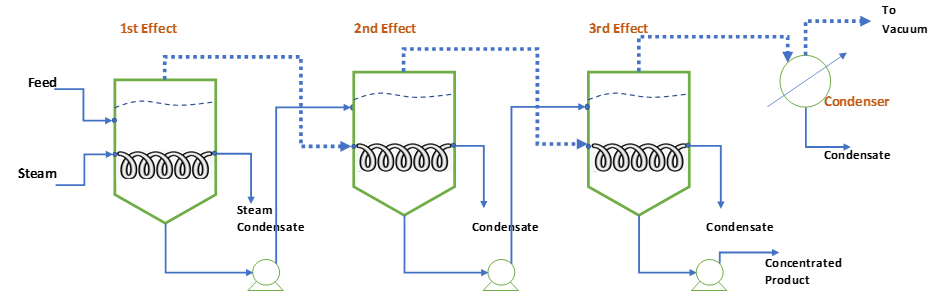

Forward Feed Operation

In this operation the feed enters into the first effect via feed pump and then subsequently flow through all the effects in downstream. Similarly, vapour from first effect enters into second and continue till the last effect. In this operation lowest temperature is at the last effect as pressure in effects keep on decreasing. Therefore, this kind of arrangements are good where final concentrated product is heat sensitive. Below is the figure for your reference:

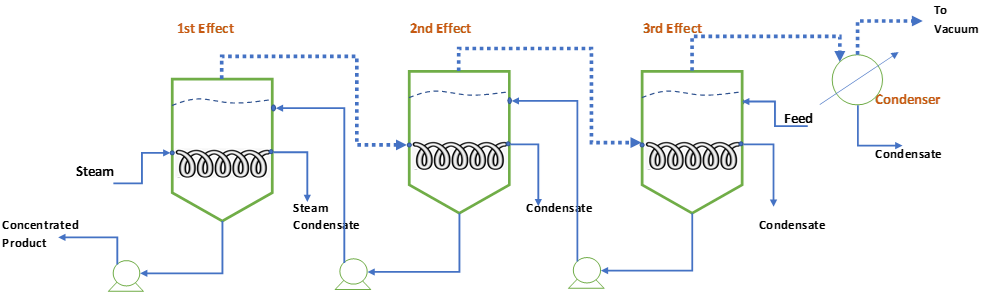

Backward Feed Operation

Here, feed enters into the last effect and the concentrated product we collect from the first effect. To understand this operation, you can refer to below figure. Here, feed flows from low temperature & pressure to higher temperature & pressure. Which is in contrast with feed forward operation. This type of arrangement is advantageous when final product is viscous. As, with decrease in temperature viscosity increases, therefore it is better option to use feed backward MEE system. This way concentrated product after each effect is at higher temperature and at higher temperature viscosity will be lower.

Other Feed Operations

Apart from above we can use mix feed operation mode also, which is the combination of feed forward and feed backward operations. In mixed feed the dilute liquid enters in between of effects, flows in forward feed to the end of the effect and then pumped back to the first effect for final concentration. Also, MEE can be natural circulation or forced circulation type.

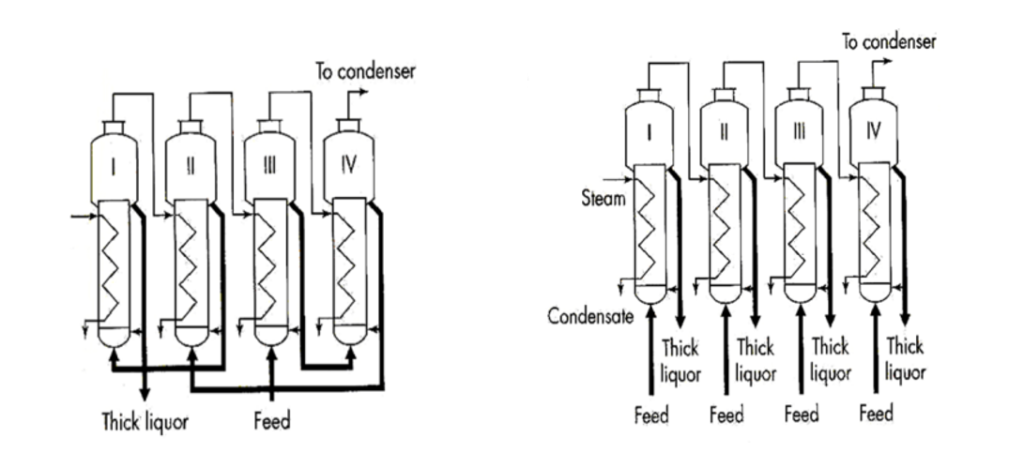

You can see another common evaporator arrangements as shown in below figure, which is more common in crystallizations. This we know as parallel feed operation. In this feed enters individually to all the effects. While, vapour from first effect enters into the second effect and continue to travel till last effect.

To improve steam economy, vapour compression may be applied to the vapour from the first effect of a multiple effect system. Thus, giving increased utilization of the steam for the MEE system. However, such a device is not suitable for use with liquid feeds with a high boiling-point rise. Because in this case, we need to compress the vapors at high pressure to superheat, so that it can provide heat to next calendarial. Finally, this will reduce the energy efficiency.

Simulation Results of a Three Effect MEE

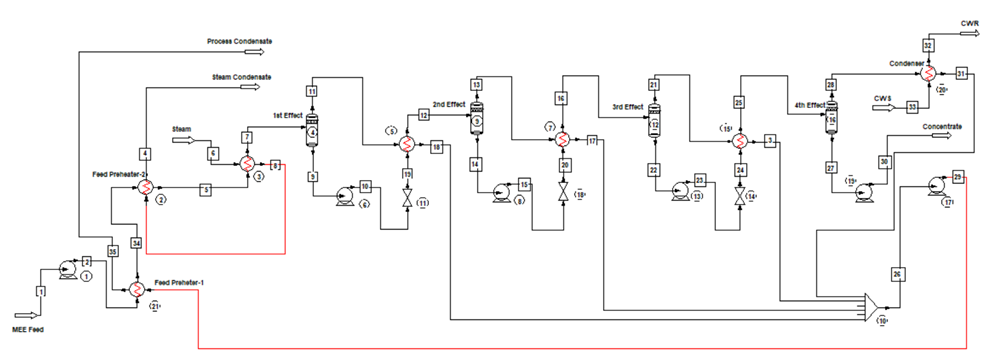

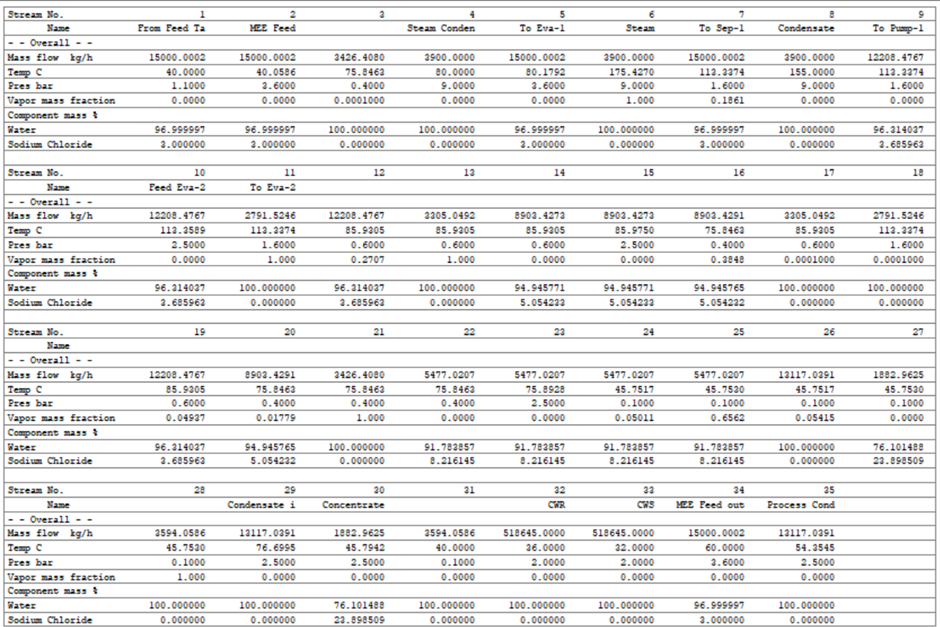

Below is the material & energy balance of a four-effect feed forward evaporator system. In this multiple effect evaporator we are concentrating a NaCl water solution containing from 3.00 to 23.90% by wt. Feed rate in first effect is 15000 kg/h at 40 0C.

First effect is operating at 1.6 bar pressure and last effect which is fourth one is operating at 0.1 bar pressure. These are absolute pressure not gauge, so in gauge pressure 1st effect is at 0.6 bar positive pressure and 4th effect is 0.9 bar vacuum. Corresponding temperatures for 1st & 4th effects are 113.33 0C and 45.75 0C respectively. Apart from this 2nd effect is operating at 85.93 0C and 3rd effect is at 75.84 0C.

In first effect evaporator we are using 9.0 bar saturated steam having temperature 175.43 0C, which has condensate outlet temperature at 155 0C.

The overall boiling point difference is: 113.33 – 45.75 = 67.58 0C

Total water evaporation quantity is: 13117 kg/h (1st effect: 2791 kg/h, 2nd effect: 3305 kg/h, 3rd effect: 3426 kg/h & 4th effect: 3594 kg/h)

Steam feed rate to first effect is: 2900 kg/h

Hence steam economy for this MEE is: 2900/13117 = 0.221 kg/kg

Cooling water requirement (32 0C supply and 36 0C return) is: 518.6 m3/h

Conclusion

The intent of this article is to understand types of multiple effect evaporators and their operation. Also, we discussed one example of four effect evaporator. We gone through the material and energy balance. I guess, this will help you to carryout the material and energy balance for your multiple effect evaporator requirement.

You can sustain the performance of the MEE by arresting the leakages and removing the scale formed in evaporator by high pressure and chemical cleaning processes. Because both the problems will decrease the overall temperature gradient between first and last effect. Other than this cooling water supply temperature at last effect vapour condenser is very important. If cooling water supply temperature is higher it will increase the condensing vapour temperature and will reduce vacuum also. In result this will reduce the efficiency of MEE. Moreover, you should regularly clean the condenser from cooling water side.

Thanks for your reading.