In chemical process industries we can see various types of columns. We use these columns for different unit operations like distillation, absorption, stripping, extraction and reaction also. Any column is a vertical cylindrical vessel having internals inside to enhance the contact surface area between phases. These phases can be liquid-gas, liquid-vapor, liquid-liquid.

During process design engineering of a column, we prepare two different documents. First, document is related with column hydraulics design and second document is for floating column fabrication inquires.

In this article we will discuss both data sheet for a Distillation Column. Let us first look into the process data sheet for column hydraulics.

Table of Contents

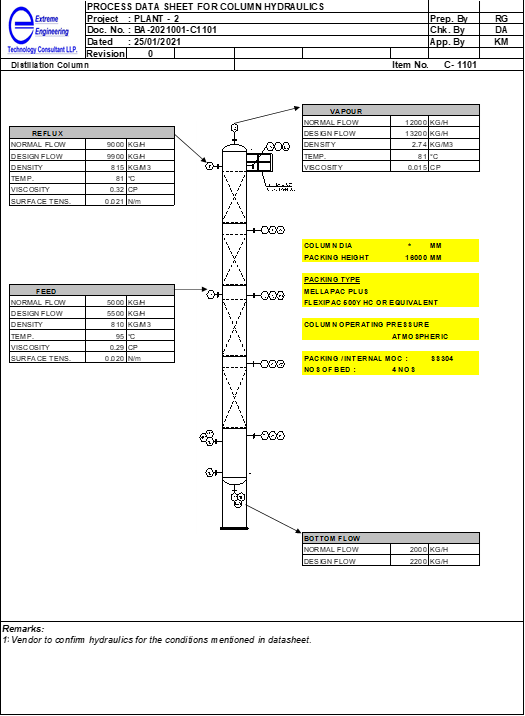

Process Data Sheet for Column Hydraulics

Column internals can be various types of trays like bubble cap, sieve, valve etc. Apart form this we use different types of packings inside the column. These packing can be either random or structured type.

The information, which we provide in PDS for Column Hydraulics are very important for the design of column internals. You need to understand any mistake in the column hydraulic data will affect distillation column capacity and efficiency adversely.

What do You Mean by Column Hydraulics?

So, first let us understand the column hydraulics. As we know, inside any column there are two streams flowing in counter-current manner. One stream flow from top to bottom and other flows from bottom to top side. So, study of various forces involved inside the column because of both the streams traffic is known as column hydraulics. We can visualize this in different types of column as below:

Distillation Column, Absorber Column, Stripper Column: Here liquid flows from top to bottom because of gravitational force. While vapor or gas flows from bottom to top side because of low density.

Extraction Column: We have two immiscible liquid phases and because of density difference lighter liquid flows in upward direction and heavy fluids flow downside.

Therefore, for the proper sizing of column diameter (i.e., trays or packing) we need this traffic flow rate information. In case of distillation, absorber and stripper columns, vapour or gas volumetric flow rate decides the required column diameter.

Attributes of Column Hydraulics Data Sheet

You can see below is the format of a Column Hydraulics Data Sheet or Specification Sheet for a Distillation Column. The correctness and completeness of this document helps the tray or packing supplier to design and fabricate column internals appropriately. This is a Basic Engineering Design Package document. So, let us go through each element of this document one by one.

Top Header

This includes information related to identification of the process data sheet or specification sheet. You should put the logo and name of your organization, column description, tag number and project name, etc. These information are very important during erection work. As, this helps the people at site for easy and errorfree identification of column internals.

Other details are document number, revision number which are important from documentation point of view. Apart from this, details of maker, checker and approver are important to trace the engineers involved in this project.

Column Feed/ Reflux / Vapor/ Bottom Flow

You need to provide the distillation column feed rate, Reflux Rate and Column Vapour Rate in kg/h or lb/h. To understand turndown ratio for the column you need to provide all three-feed rates namely, at minimum, maximum and normal conditions. This information helps to design the column internals like collector, distributors, downcomers, risers, etc.

Other than this column feed temperature is mentioned. Also, physical properties density, viscosity and surface tension at operating conditions should be provided for all the streams.

Packed Height and Column Diameter

Based on simulation results or lab trial data we can estimate and provide the required stages/packing height. However, if you want to get validate this required packing height or tray design from column internal supplier. Then you need to supply all other information like, feed composition, top and bottom product compositions. Also, you need to provide vapour pressure data for all the components to generate VLE data.

In some cases where, physical properties of the components are not available, a pilot distillation trial is very important. Based on pilot trial data, column internal supplier can design and supply the column internals for a commercial column.

Other Information

On column hydraulics specification sheet, you need to mention column operating pressure. We need to mention at what pressure it is operating (i.e., atmospheric, positive pressure or vacuum).

Apart from this we need to mention MOC (material of construction) of the column internals. This depends on the fluid corrosion properties and operating temperature.

Moreover, in case of packing we should provide, how much packing segments we need and height of each segment. However, for standard practice packing height of each segment should not be greater than 5 meters, as it will create channelling problem. Also, you need to mention feed point location very clearly. In case of trays, we need to specify number of trays and spacing between the trays.

In remarks section of the process data sheet, we can provide any specific details. Which we think is very critical for the design of column internals like, explosive tendency or temperature sensitivity of fluid. If there is chocking or polymerizing tendency of fluid, you should mention it clearly.

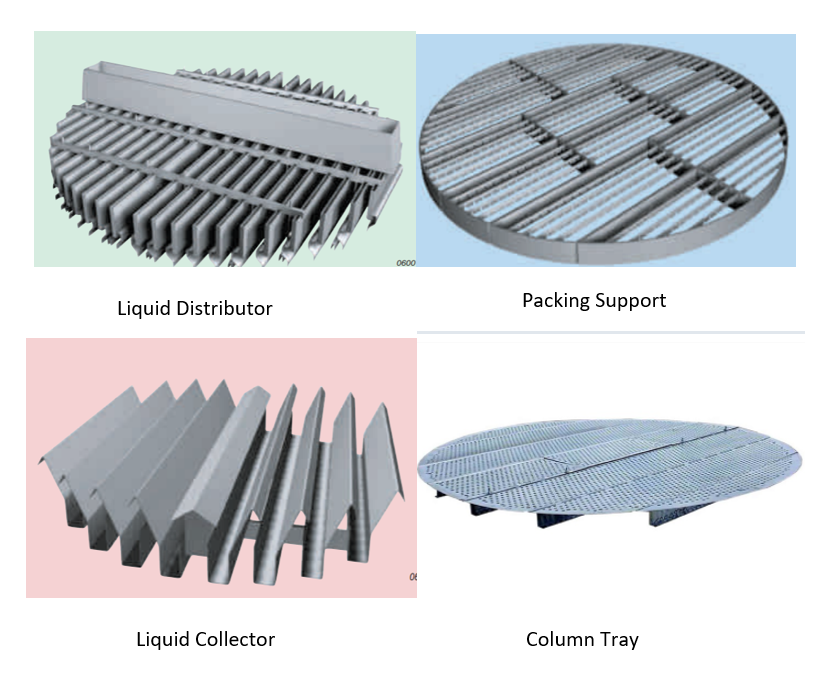

Column Internals

So far, we discussed the Column Hydraulics Data Sheet, now we will look into the Process Data Sheet for the distillation column.

After freezing hydraulic data for a distillation column, we are through with the process design of column internals. When we talk about column internal design is means different details for tray and packed column as below.

Tray Column Internal Details – This comprises type and dimension of trays. And, the details of tray construction whether in single piece or in multiple segments. Numbers of trays and it’s spacing. Moreover, the tower attachment details to fix these trays inside column are there.

Packed Column Internal Details – Various information includes about column diameter, segment height, packing support details, distributor and redistributor details. Apart from this, other information is also there, which are required to provide the tower attachments to fix the packing supports and distributors.

Below are sketches of column internals for your reference.

For subscribing quotations for column internals, you can float inquires to the Sulzer, Koch-Glitsch, Kevin Enterprises, Fenix Process Technologies, etc. Among these Sulzer and Koch are pioneer in this field.

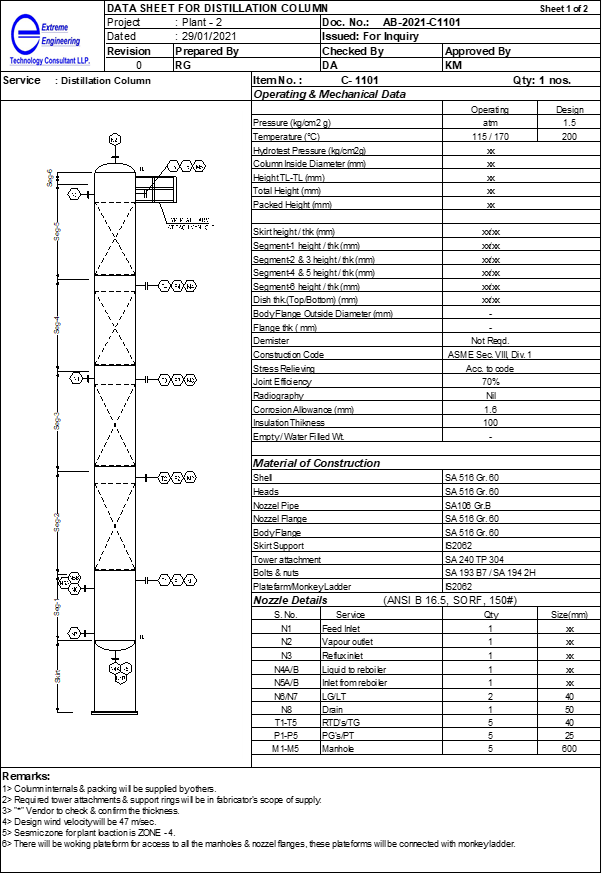

Process Data Sheet for Distillation Column

So, after getting the information about column internals, we can design the column in which these internals will be fixed. We require this distillation column PDS to send the inquiry to column fabricators.

Hence, to understand the Distillation Column PDS we will go through the below format and will discuss each component of it.

Operating & Mechanical Data

You can see in above PDS, we need to mention operating & design temperature/pressure data. This is required for mechanical design of the column. Moreover, hydrotest pressure is required to test the column after fabrication.

As we have column dimension from hydraulic data sheet, hence we can provide the column inside diameter, packed height or tray numbers and total height requirement. You should carefully check the column height requirement to accommodate the packing or trays and packing support, liquid collector & distributors.

Moreover, we need to mention column design code like ASME, Section VIII, Division I or GEP (Good Engineering Practices). Also, we mention stress relieving code, joint efficiency and radiography requirements. Apart from this we need to mention corrosion allowance and insulation thickness.

For foundation or structure design to support the column, you need to provide estimated weight for empty and filled column.

Material of Construction

You need to provide the material of construction for various part of column like shell, body flange, nozzle pipe, nozzle flanges, column inside fixtures, skirt support, bracket, lifting lugs etc. Other than this you need to provide the MOC for gaskets, fasteners, plate farm, ladder, etc.

Nozzle Schedule

Here we provide details for all the nozzles required in a distillation column. Commonly, in every distillation column we require, Feed Nozzle, Vapor Outlet Nozzle, Reflux Nozzle, Inlet/Outlet connection for reboiler, Column bottom outlet, Vent Nozzle, Manhole (in case of large diameter columns > 1.50 m), Handhole, Drain point, Level gauge & level indicator nozzles, safety valve nozzle, temperature and pressure indicator nozzles.

Other than this many times we require light glass & sight glass nozzles also, to see the liquid flow inside the column. In nozzle details we provide the standards to follow (i.e., ASME/ANSI or BIS) for flange dimensions.

Moreover, we need to mention nozzle pipe schedule & thickness with flange ratings. Also, nozzle tag number and quantity of nozzles is there in the table.

Remarks

In this section we can provide miscellaneous information, which are common for a distillation column. You can see in above format there are sample comments for your reference. Based on your specific requirements this information can be customized. Whole purpose here is to provide all the general clarification to the fabricator.

Conclusion

This article is very helpful for the preparation of process data sheet for column hydraulics and column fabrication. So, column hydraulics data sheet is the first document, which we use to float the inquiry for column internals. After that, based of column internal details we prepare column fabrication process data sheet. This column fabrication data sheet we send to the column fabricators.

Based on these data sheets vendors and fabricators submit their quotations. Afterwards, we do the technical bid evaluation and give these technical recommendations to procurement group, to place the purchase order.

Thanks for reading and looking forward for your valuable comments.