Digital transformation, Artificial Intelligence (AI) and Machine Learning (ML) in chemical process industries are in starting phase. However, we have witnessed huge transformation of chemical industries. Before 18th century production of chemicals was in batch mode. The plant operation was totally manual and human dependent. At that time product delivery was on top priority as cost and quality was not an issue. When, demand started increasing and there was pressure on supply side. Therefore, to meet the demand manufacturing started shifting from batch to continuous process. And this revolution from batch to continuous process increased the product supply into the market.

Due to abundant supply and presence of many market players started stiff competition. However, this competition was good for consumers. This was the era when companies were facing pressure on the product cost and quality to sell their products.

Whoever, will provide the product with lowest cost and best quality will be market leader. This was time of next industrial revolution, which introduced process control and automation. This industrial change enabled manufacturers to provide products with lower cost and consistent better quality. Moreover now manufacturing process was more safer and robust.

Table of Contents

Digital Transformation

APC (Advance Process Control) is the demand of present time. This will place the industries at next level. Also, APC is inevitable for the next industrial revolution. This we also know as Industry 4.0 or Digital Transformation. Implementation of APC eliminate or minimizes the human intervention in process control. Because, human intervention is the main source of special cause variations. Special causes are beyond the natural behavior of a process and their prediction is next to impossible.

By APC implementation we can minimize this process variation as the operation will be human independent. Therefore, it is easy to predict the equipment or machine behavior using machine learning algorithms. APC implementation can reduce our variable cost of production and increases productivity of the plant. As a thumb rule we can achieve around 10% reduction in raw material and utility cost by APC implementation.

Potential Benefits of Digital Transformation

Chemical plant digital transformation is very important for next level improvement wave. This can improve process control through the use of artificial intelligence, machine learning and more robust data science modelling. This will make it possible to derive insights which was not possible before. We will achieve greater value through improvements in operations and reliability, and ultimately to maximize margins through operational excellence programs.

So, digital transformation have potential to enable our processes to become smart and intelligent enough. However, use of AI and ML is new in this area but in future we see smart unit operations. When I say smart, I mean these process equipment will be able to act like humans in case of any disturbances and abnormalities they will be able to control their parameters on their own to maintain required output with consistent quality and capacity. Within plant these equipment will be capable to communicate with each other to manufacture the products with better quality, maximum productivity and with safety. Moreover, equipment will be able to self-diagnose and prescribe the solutions in advance to avoid plant performance degradation.

Data Science, AI, ML & DL

The Data Science is the field, which help us to analyse real time plant data and provide the knowledge to develop ML models. Generally, data scientists use Python as a programming language for data analysis and machine learning. Because, it is easy to understand, has large number of libraries, easy & powerful implementation and a huge support community.

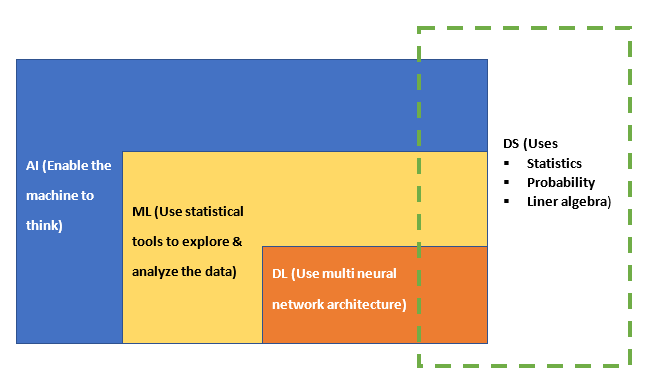

When we talk about machine learning in a Chemical Plant, lots of buzz words come in our mind such as, “What is AI, ML, DL and Data Science?”. So, we will discuss it and I am sure after this your confusion should be clear.

What is AI?

Artificial Intelligence (AI) enables the machine or equipment to think like human. Machines will act without human intervention against any deviation or abnormality and can make best possible decision among various available options. Developing Artificial Intelligence in a machine is the final goal in Data Science. One of the good example of AI application is a self-driving car.

What is ML?

Machine learning (ML) is the subset of artificial intelligence. It provides us the statistical tools to explore and analyse the data. Machine learning (ML) is the study of computer algorithms that improve automatically through experience by use of data. We can divide machine learning in four parts as below:

Supervised Machine Learning

Supervised Machine Learning has labelled data to predict future. Labelled data means we know our input and out variables. Supervised machine learning uses regression and classification algorithms. In case of continuous variables we use regression and for discrete variable we use classifier to predict output variable. The example of supervised machine learning algorithms are such as, random forest, support vector machine, liner regression etc. Some examples of supervised machine learning models are weather forecasting, prediction of train ticket confirmation etc.

Unsupervised Machine Learning

When we don’t know what is our output or we can say data are not labelled. We can use this to solve the clustering problems, based on the similarity. It will group them and brings order to the dataset and makes sense of data. K-mean clustering, Hidden Markov Model, Principal Component Analysis are some examples and below are examples ofr uses of unsupervised learning:

- Biology – for genetic and species grouping;

- Medical imaging – for distinguishing between different kinds of tissues;

- Market research – for differentiating groups of customers based on some attributes

- Recommender systems – giving you better Amazon purchase suggestions or Netflix movie matches.

Semi Supervised Machine Learning

When some part of the data is labelled and large part of the data is not labelled, in that case we use semi-supervised machine learning. As it works with both and in between supervised and unsupervised learning algorithms, therefore is called semi-supervised machine learning.

Reinforcement Machine Learning

It use the trial and error method to churn out output based on the highest efficiency of the function. The output is compared to find out errors and feedback which are fed back to the system to improve or maximize its performance. The model is provided with rewards which are basically feedback and punishments in its operations while performing a particular goal.

What is DL?

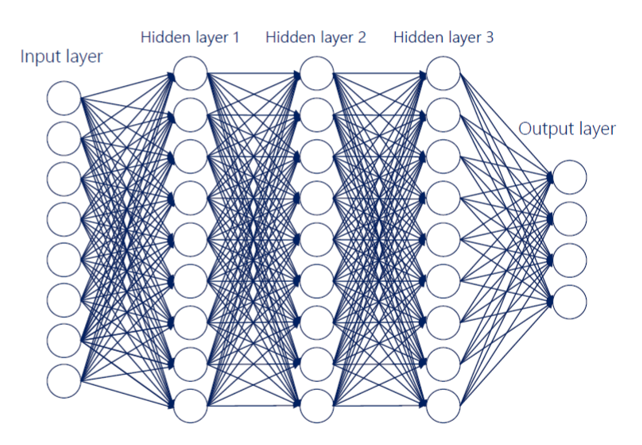

The idea behind the Deep Learning is to develop the algorithm to mimic a human brain. Well known use of DL is to solve more complex problems like face recognition, text reading etc. In deep learning we use multi layer neural network architecture to create the models.

What is Data Science?

Data Science uses statistics, probability and linear algebra to develop the machine learning and deep learning models. The final objective is to derive the artificial intelligence from these models, which enable the machines to think like human. This will make possible for plant equipment to work automatically without any human intervention.

Conclusion

The challenges to adopt the AI in chemical industries are cost of up-gradation of existing instruments and control system, data security threat and clear corporate strategy. Subsequently, digital transformation of the plant will enable real-time access of operating data.

Apart from this need for new skills and lack of quality data is also a big problem, as data is the blood for ML models. Another reason for the slow uptake of AI is an insufficient understanding of benefits and available use cases. However, industries have started using available machine learning solutions in rotating machines to predict abnormality and condition monitoring. These solutions capture the vibration data or current signature data through sensors fitted on motor. On IoT platform this data is analysed in machine learning algorithm to predict the failure of compressor or pump. Also, condition monitoring of pumps, compressors, vapor compression refrigeration unit etc are excellent use cases.