This is in continuation of my last article on the costing of shell & tube heat exchanger. In this article I will be sharing & discussing the excel sheet for distillation column cost estimation. This will give us clarity about the equipment cost which we can use as a basis to validate the various quotation received from different vendors. Which is important for further negotiation with the fabricators before placing the purchase order.

Table of Contents

Details of Column Costing Sheet

So, first let us discuss the distillation column costing sections. Generally, we can divide this in following sections:

Material Cost

This includes the cost of material purchased which is required for the fabrication of the distillation column. For costing purpose, we need to consider raw material cost which includes finished equipment weight and waste material. Waste material is the remaining metal after cutting out the required portion of metal from sheets and pipes. This is around 10% of the finished equipment weight. The various types of material include plates for shell, channel & dish ends, plates for flanges, plates for skirt support, material for ladder & platforms, nozzle pipes & flanges, material for column attachments, etc.

Fabrication Cost

For distillation column fabrication there are lots of activities involved which are performed by skilled fitters & welders. Based of the fabrication drawing cutting, plates rolling & welding is done. The fabrication of body flanges in case of segmented columns. While in case of single piece monobloc column we need to fabricated ladders & service platforms for access of manholes. So, charges of fitters & welders, consumables for welding & cutting, various machine charges, electricity charges, etc. are the part of equipment fabrication cost. This fabrication cost is generally in the range of 30% to 50% of the total material cost. For small size and complicated equipment fabrication cost is considered higher side (i.e., 40-50% of material cost). While for simple and large size equipment we should take fabrication cost lower side (i.e., 30 to 40% of the material cost).

Cost of Column Internals

Other than above we need the costing for column internals also. In our plant either we use packed column or tray type columns. So, for the costing of packing whether it is structured or random can be taken from vendors or you can refer to past purchase orders. Once you have per m3 cost of the packing, this can help you to estimate the column packing cost. And, for the costing of plates we can estimate the weight of single plate and multiply it with material and fabrication cost. However, it is better if we get this cost from tray supplier directly or can refer some past purchase orders.

Other Cost

This comprises various charges like testing and inspection, painting and insulation (if done at vendor site), taxes & freight charges are also the part of this cost. Other than this packing & forwarding is also the charges which add to the final equipment cost.

Distillation Column Costing Spread Sheet

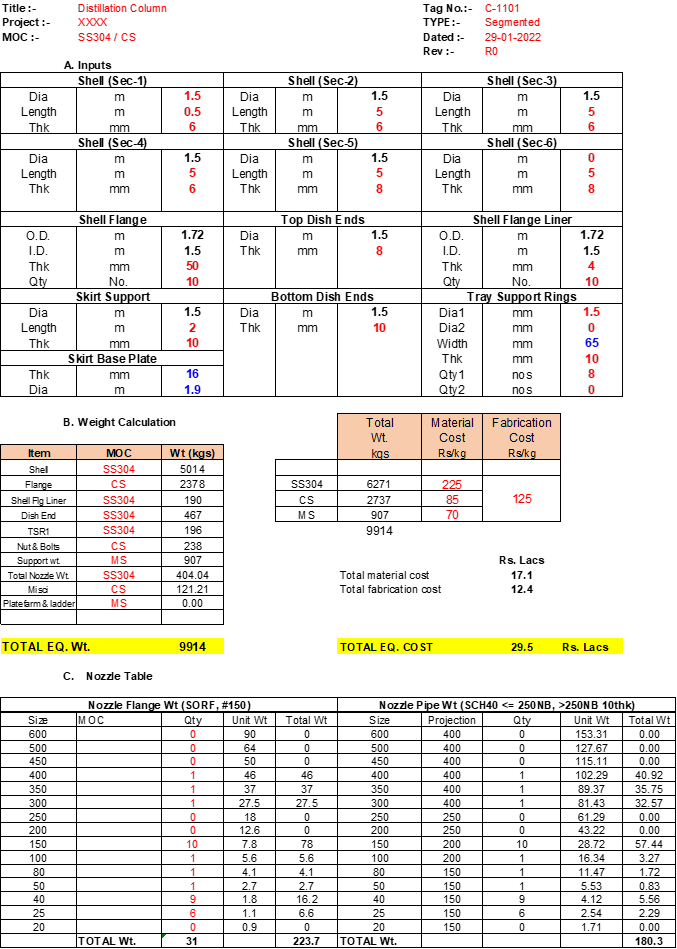

Below is a format to do the costing for distillation column, in which you need to provide various data of a distillation column or other columns (i.e., extraction, absorber, stripper, etc.). To furnish these data, you need distillation column data sheet or fabrication drawing.

Input Values

Please provide all the inputs as marked as red, such as diameter, shell length, shell plate thickness, channel shell length, thickness of channel shell & dish ends, flange thickness, etc. Apart from this you can provide the nozzle details in nozzle table for their weight estimation. You can customize this based on your requirement if there is change in flange rating.

Moreover, in case you wish to have lined body flanges you can change this accordingly. For that we need to change the MOC of body flanges from SS to MS or CS and change the total weight for SS & MS will change accordingly. Similarly, if there is change in the type of column you need to input data in this sheet accordingly. However, this sheet can be used for segmented column or single piece column (i.e., monobloc type) costing estimation. In above figure, I have considered a segmented distillation column (having body flanges) having six segments. Made of SS304 body and CS flanges having SS304 liners to reduce the equipment costing.

Apart from these you need to provide material cost and fabrication cost, which is latest one. This you can easily get from the purchase department people. To download the excel sheet for shell & tube heat exchanger please click here.

Conclusion

I am sure this will help you for distillation column cost estimation. Furthermore, you can modify this calculation sheet as per your requirement to estimate the costing for absorber column, stripper column, extraction column, etc. Apart from this cost of column internals such as trays, packing (i.e., random or structured) we can get from vendors or refer to the past orders.

Thanks for reading.